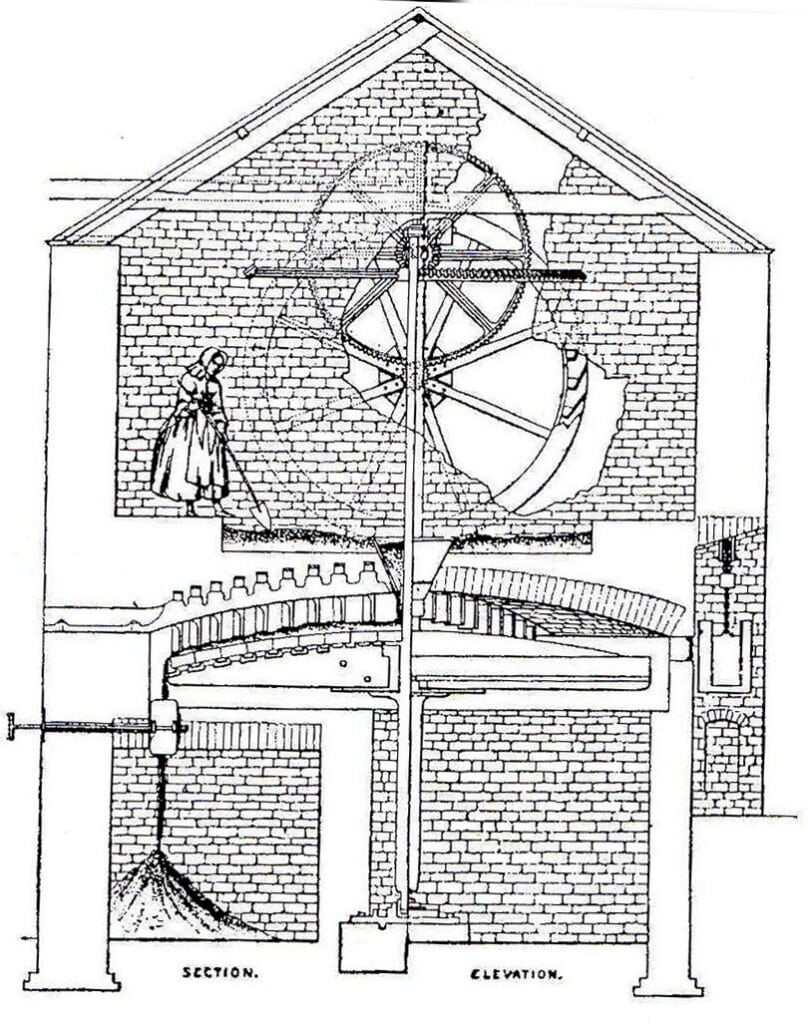

To most people the Cornish mining industry is about tin and copper, with perhaps a certain amount of lead, silver and zinc thrown in. Although this may represent a large part of the truth, other material ores have also been of great importance to the industry, and one of them, arsenic, can truly be said to have been the factor which rendered 20th century mining in Cornwall viable. Arsenic treatment has had a long history in Cornwall, although for most of the time it has been considered merely as a nuisance to be expelled from the dressed metallic material. Arsenic first became a problem to tin dressers in the late medieval period, when lode material was being increasingly mined and the arsenides and sulphides, usually weathered out of the stream tin by long exposure, was more frequently met with. By the end of the Middle Ages techniques had been developed to remove these contaminants by roasting the hand-picked ore, or partly concentrated tin stuff. This was roasted to a red heat, allowing air to pass into the material and to oxidise the arsenic mineral to the volatile arsenious oxide, which could be carried off in the fumes. The human, animal and vegetable life around these primitive burning houses probably suffered as a result of these noxious fumes. In his latest book, The Cornish Arsenic Industry, Bryan Earl relates the history of arsenic treatment in Cornwall and West Devon, and quotes from a 17th century description of a burning house. The account, from The Philosophical Transactions of the Royal Society, dated 1671, describes what is undoubtedly a very early method of ridding tin ore of arsenic contamination. The burning house structure is massive, being made of large granite blocks, topped by a “moor-stone” measuring six foot by four foot. The working part resembles a “common oven”, with a chimney at the front. A man with a “coterake” controls the quantity to be placed into the oven, and once the hole at the top is covered by turf, to enable the flames to “reverberate the stronger”, he sets about raking the ore, “that all parts of the Mundick (containing the arsenic) may get uppermost of the Tin, and so be burned away…”. There are early references to these burning houses from the 16th and 17th centuries and a map of Perranarworthal, dated 1696, found in the Lanhydrock Atlas, illustrates one with two reverbatory furnaces alongside each other. Mr. Earl has discovered such a burning house, almost identical to the one described in 1671, near to Relubbus, on the Hayle River.

Remains of a Brunton Calciner building at Wheal Busy, Chacewater. Until the beginning of the 19th century, arsenic was seen as something to get rid of, but increasingly, especially abroad, arsenic was viewed as a commodity which had a marketable value. In 1817, one Dr. Richard Edwards of Falmouth, set up a works at Perranwell specifically to extract refined arsenic from mine waste. Mines troubled with arsenic in their ores were encouraged to build collection flues into their burning house arrangements, so that the product could be saved for sale. In 1835, an arsenic refining plant was set up at Bissoe, establishing it as the centre of arsenic production in West Cornwall. The now-familiar long “lambreths” (labyrinths), or collecting flues grew from those early endeavours, and the black arsenic soot was supplemented by the snow white powdered refined arsenic. Bryan Earl describes precisely how these processes developed and worked, producing a valuable commodity, which could be exported all over the world. The cotton growers of the southern states of the U.S.A. dusted their crops with white arsenic to kill the dreaded Bo Weevil, the potato farmers of America fought the Colorado Beetle with it; the chemical and paint industries found a hundred uses for it; virtuous ladies whitened their hands with it and not-so-virtuous ladies disposed of their husbands with it! By the end of the 19th century, arsenic generated an important part of the income of many Cornish mines, and as the 1900s got underway, mines like South Crofty and East Pool, two of the great survivors of the 20th century, operated several Brunton Calciners each, and owed their continuing existence to their arsenic sales. When times were particularly hard, the arsenic sales figures were often the difference between profit and loss. South Crofty particularly remains today due to its income from that source between 1900 and 1950. After this, there tended to be less arsenic in the ore and a massive world over-production. It was no longer economically viable to extract the material to sell. By the early 1950s, arsenic contamination was less of a problem, and by then both Geevor and South Crofty had abandoned their calciners and were using a flotation method to get rid of the arsenic. The once-familiar high chimney stacks and calciners, joined by the long and tortuous “lambreths”, are gradually disappearing as progress, “surreyfication” and development destroy the old mining landscape, but, as Bryan Earl points out, the old buildings associated with an industry once so profitable to the Cornish, have a certain “romance” about them.